Sunlight: The Greatest Threat to your Wood Door

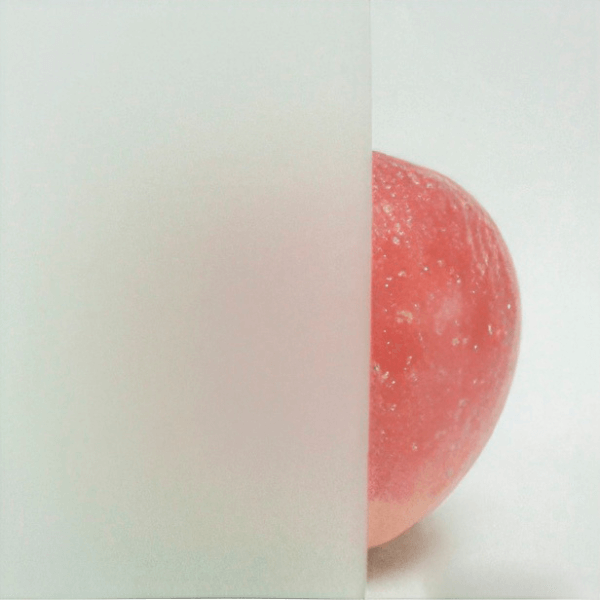

In considering how to preserve the life of your pivot door, please understand that the sun—not water, cold, or wind—is the greatest potential threat. The most important step you can take in caring for your pivot door is to protect the wood face from the sun’s UV rays, heat radiation, and visible light. Your pivot door face is made from wood, which is a living material. As a living material, the wood can still move and change shape. Any change in climatic conditions has the potential to cause wood movement. Rain, snow, heat, cold, sitting water, changes in temperature, and changes in humidity all have potential to cause shrinking, warping, or delamination. However, the single most damaging force will be the sun. For this reason, it is important to have sun-blocking features like an overhang or landscaping to keep the sun off of your pivot door as much as possible. It is also important to consider the color of your pivot door’s finish: a darker finish will absorb more sunlight and multiply the potential for issues with wood movement such as cracking and warping. By finishing the pivot door with at least three coats of a sealer that contains UV blockers and maintaining the sealer with regular attention, you will have the best chance of preserving the wood’s shape and color.

You have been contracted by the purchaser to seal a pivot door. Because each climate and installation site are unique, we advise our customers to lean heavily on the advice of their local sealing professional, someone familiar with local conditions. We do not provide strict guidelines for how to seal the pivot door, though we offer this Care and Finishing Guide to assist in the finishing process.

- As a professional located in the region where the pivot door is to be installed, you are in the best position to advise on the treatment and care of a wood pivot door.

- Pivot Door Company does not require the use of a particular finishing product or brands; however, we do require the customer seal the pivot door for the warranty to be in effect.

- The more powerful the sealant, the more protected the pivot door will be. Commercial or industrial grade sealers will offer the greatest protection.

- We advise our customers that a darker finish can lead to problems with wood movement as it will absorb more heat and shrink.

- We encourage the customer to work with you to create a maintenance plan for the pivot door, including a maintenance schedule.

Because Pivot Door Company doors are crafted with only the finest materials, you can choose from a wide variety of stain or paint possibilities. Paint dealers have a broad selection of color chips on-hand to demonstrate the look you can achieve when staining fine wood.

If you choose paint instead of stain, you can apply either oil-base or latex resin-base paints over a primer. However, take care in following the finishing instructions provided here. Also, be sure to evaluate the conditions your pivot door must endure, such as direct exposure to severe climates, before deciding on the specific finish to use. All pivot doors must be finished before or at the time of installation.

Caution: Pivot Door Company cannot evaluate all the available paints and stains, nor the customer’s specific application requirements. Your paint dealer should know of suitable finish systems that give satisfactory results in your region. It is highly recommended that top quality finishes be selected, and the application instructions on the container be followed explicitly.

1. Final Sanding

While pivot doors are sanded in the factory, be prepared to perform a minimal amount of sanding in preparation for finishing before applying the first coat of finish. Sand to remove all handling marks, raised grain and other undesirable blemishes by sanding all surfaces with 180 grit sandpaper. To avoid cross-grain scratches, sand with the grain. NOTE: small amounts of grease, oil or pitch can be wiped clean with mineral spirits.

2. Cleaning

After sanding, clean pivot door thoroughly with a cloth to remove all dust or foreign material. Do not use caustic or abrasive cleaners.

3. Sealing

Pivot doors must be properly sealed prior to installation of hardware and exposure to moisture or weather. Properly finish pivot door immediately before prolonged storage.

4. All Six Sides

All surfaces of the pivot door must be properly finished. The edges (top, bottom and sides) should be coated with each and every coat of finish that is applied to the exterior surface of the pivot door. Doors must be dry before finishing.

5. Finishing Pivot Doors with Glass

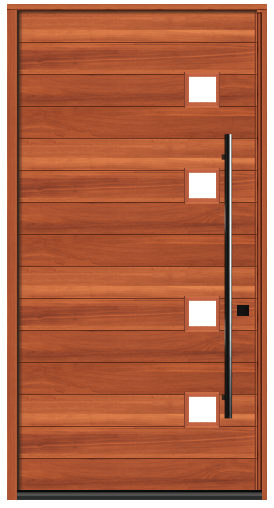

On pivot doors that are glazed with clear glass, the finish used should be flowed from the wood slightly onto the glass. This will provide assurance against water leakage and protect the glazing compound “putty” from drying out.

Note: It is the finisher’s responsibility to protect glass prior to and during finishing. If using tape, conduct a test of the tape being used on a small area of the glass before applying to a large surface. After finishing, remove the tape as soon as possible.

Application of Stain

The first finishing coats should be any stain you want to apply. Staining colors the pivot door. Apply stain to the pivot door as per the manufacturer’s instruction. Choose a stain with an alkyd-resin base. Under no circumstances should a lacquer-based toner or any other lacquer-based finish be used on exterior pivot doors. We recommend using a UV resistant stain.

Application of Sealer

After staining, apply at least three coats of exterior grade clear finish. Choose a solvent-borne (alkyd resin-base, polyurethane resin-base) clear finish. Choose a sealer that has UV blockers added to protect from the sun. Do not use only a wax or oil. If you use only a wax or penetrating oil (e.g., Tung or Teak), the finish will wear off in a matter of months and your pivot door will be subject to the elements. You want to choose a sealing product (e.g., a polyurethane) that forms a plastic like covering over the wood. Waxes and oils alone do not do this. Be sure to coat all six sides of the pivot door (including sides, faces, top and bottom).

Note: Follow product instructions for sanding between coats. All stain-and-clear finishes will perform measurably better if protected from the direct effects of sunlight and weathering, and refinishing will not be required as frequently.

Application of Paint Finish

Either oil-based or latex resin-based exterior grade paints may be used with success on panel pivot doors. Oil-based paints offer more resistance to the passage of water (liquid and vapor) than latex resin-based paints, but the latter have better durability and color retention.

Pivot doors should be sealed with a good quality primer followed by two top coats of either an oil-based or latex resin-based paint. Of course, both primer and top coat should be made by the same manufacturer and designed to be used as a combination.

Note: Where possible exposure to direct sun or rain is a factor, to keep your wood pivot doors beautiful, they require periodic resealing or painting dependent on weather or moisture exposure. Do not use dark colored stains or paint on pivot doors exposed to sunlight, as some expansion and contraction of pivot door parts may occur. Be sure to coat all six sides of the pivot door (including sides, faces, top and bottom).

Finishing Pivot Door with Glass Units

- Use a silicone or caulking bead (must be compatible with paint) around the perimeter of each glass pane. This will seal the putty and prevent any moisture from running directly into the pivot door.

- Ensure all finish coats are allowed to flow into the glass area at least 1/16″.

- Ensure all coatings that go on the surface of the pivot door are also applied to the top and bottom.

- Coat all six sides of the pivot door (including sides, faces, top and bottom).

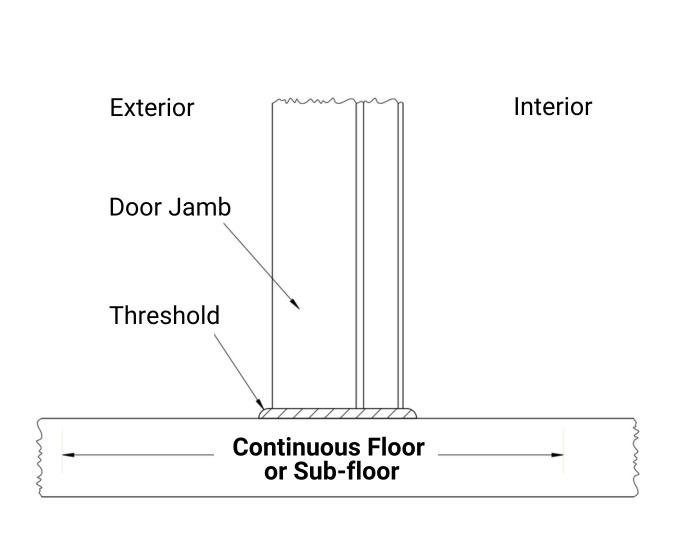

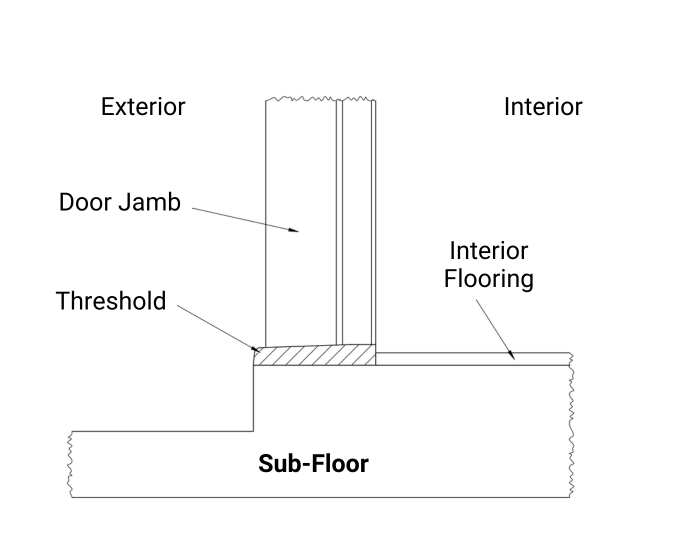

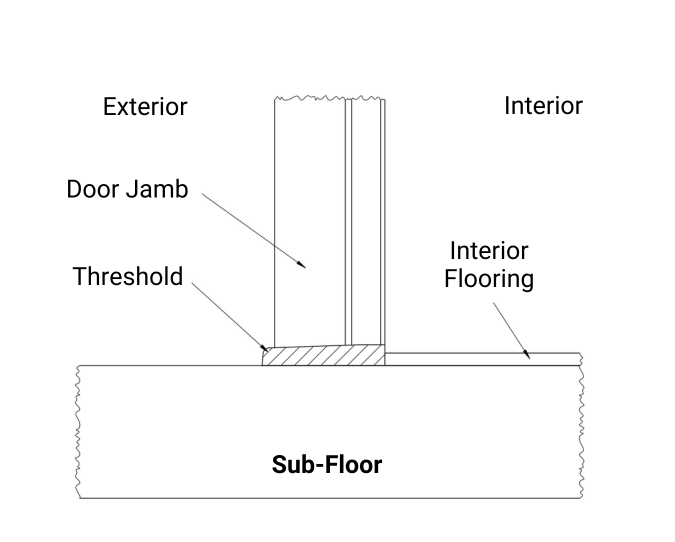

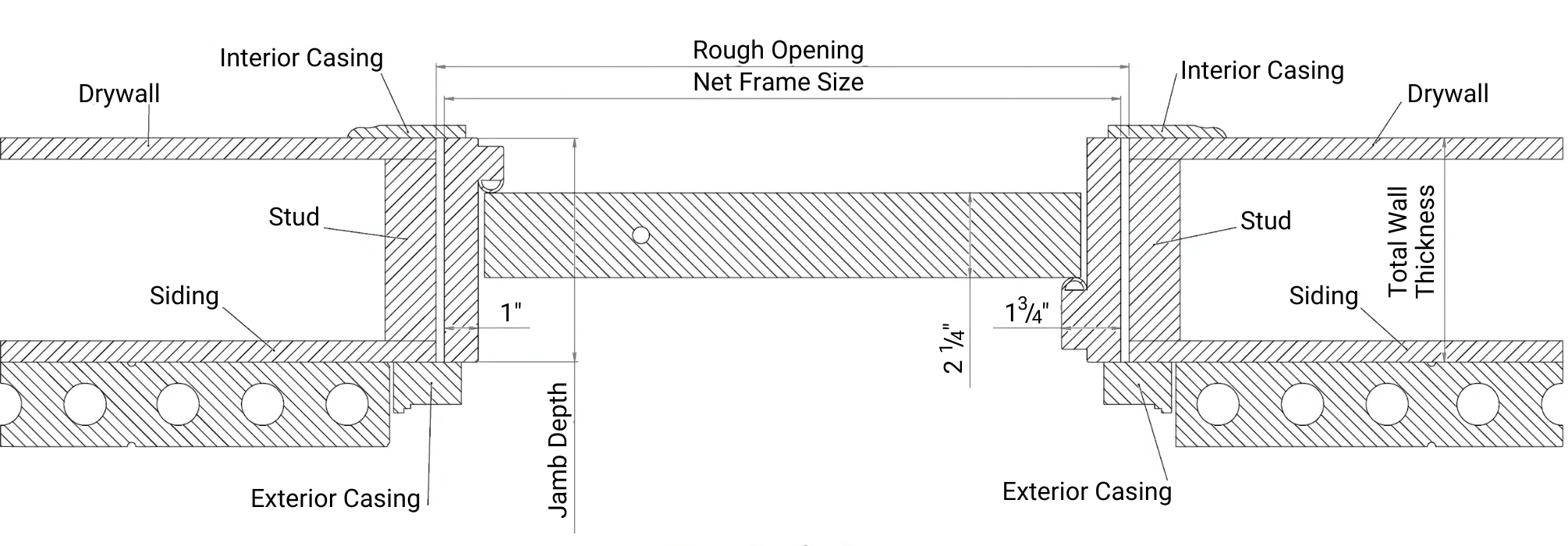

Jamb-to-Sill Specifics

- Caulk at sill-to-jamb leg connection.

- Use corner pads where sill meets jamb.

- Flood flush bolt hole in sill with caulk or silicone.